SMART project driving growth through eco-friendly innovation in light engineering sector

In Bangladesh, the light engineering sector plays a vital role in the national economy, but it also faces significant challenges. Many of its microenterprises operate with outdated, resource-intensive technologies that contribute to environmental pollution and limit profitability. The story of Sarkar Metal & Engineering, a small foundry in Bogura, highlights a path of transformation that addresses these issues through Resource-efficient and Cleaner Production (RECP) practices, proving that environmental responsibility can lead to economic viability. It is a testament to how targeted support and strategic partnerships can transform an entire industry, one enterprise at a time.

Founded in 2015 by Md Shihab Uddin Sarkar, the company initially used a coal-powered foundry to produce parts for large industrial clients like RFL. While the business started with promise, by 2020 it faced a crisis. The market for its primary product, tube-wells, had collapsed, and soaring electricity costs, which had doubled from BDT 5 to 10 per unit, made the business model unsustainable. Faced with the risk of closure, Sarkar’s once-promising venture stood on the edge of survival for a substantial period of time.

In 2024, Sarkar attended a workshop on RECP technology organized by Gram Unnayan Karma (GUK) under the Sustainable Microenterprise and Resilient Transformation (SMART) project. The workshop presented a new perspective: that cost reduction and environmental protection could go hand in hand. Inspired and determined, Sarkar decided to reinvent his business.

With support from the SMART project, Sarkar received hands-on training in RECP practices, e-commerce marketing, and environmental certification. Backed by a BDT 10 lakh Common Service loan from GUK and a grant for an automated induction furnace, he made a strategic move. He replaced his polluting coal-based foundry with automated induction technology.

This was more than an upgrade, a fundamental shift. The change resulted in reduction of production costs, a significant improvement in product quality, and a near-zero reduction in waste generation. Beyond the technology, Sarkar implemented modern waste management practices and planted over 1,200 timber and fruit trees on his property. He also focused on his employees’ well-being, providing safety equipment and occupational health training. As Sarkar himself reflected, “This wasn’t just an upgrade—it was a complete transformation. Production costs fell by 20-30%, product quality soared, and waste generation dropped to nearly zero. My foundry became not just a workplace, but a model of safe, sustainable, and climate-resilient industry.”

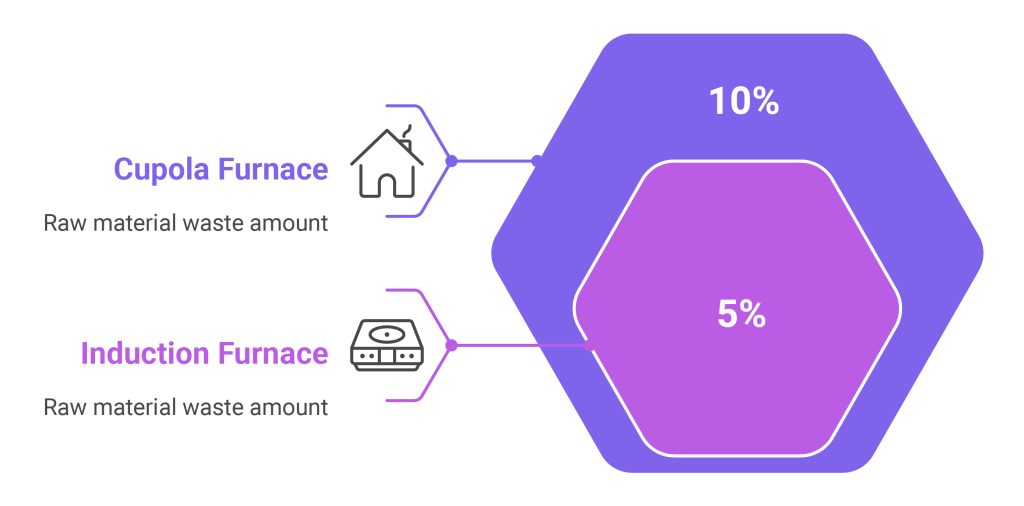

The transition from a coal-powered cupola furnace to an automated induction furnace offers a clear set of benefits. A cupola furnace produces a raw material waste of about 10% and emits approximately 550 kg of CO2 per ton of material produced. In contrast, an induction furnace reduces raw material waste to about 5% and has no direct emissions. While the cupola furnace is limited to producing cast iron and requires 250 KWh of electricity plus 100 kg of coal per ton, the induction furnace is more versatile, capable of processing steel, cast iron, aluminum, copper, and brass. It requires 1000 KWh of electricity per ton, but eliminates the need for coal and its associated costs and pollution.

The success of Sarkar Metal & Engineering is part of a larger, coordinated effort. According to A. K. M. Mahfuzur Rahman, Deputy General Manager of the Bangladesh Small and Cottage Industries Corporation (BSCIC) in Bogura, the government has long been working to address key challenges in green manufacturing. Rahman notes that these include “a significant lack of awareness among entrepreneurs about sustainable practices, insufficient legal frameworks and enforcement mechanisms, limited technical knowledge regarding clean production methods, inadequate financial capacity among microenterprises to invest in green technologies, and poor coordination between various government agencies and development partners.”

He believes the SMART project’s collaborative approach has aligned well with national goals. “Working hand-in-hand with BSCIC, the project has initiated comprehensive activities to sensitize light engineering entrepreneurs through strategic observation of national and international environmental days, targeted awareness campaigns, and regular stakeholder meetings. This approach has proven highly effective in bridging the gap between policy intentions and ground-level implementation.” Rahman adds that he is particularly impressed by how the project “ensures both work-friendly environments and green growth through targeted support mechanisms.”

The partnership behind the SMART project involves the World Bank, Palli Karma-Sahayak Foundation (PKSF), and GUK. Dr Md Mahbub Alam, Senior Director at GUK, describes this collaboration as pivotal. “The partnership with the World Bank, PKSF, and Gram Unnayan Karma (GUK) has been crucial in driving success by combining international expertise, national policies, and grassroots networks. The World Bank and PKSF provided technical guidance and ensured an effective financial mechanism, and GUK delivered community-level support. This multi-tiered model enabled comprehensive assistance ranging from awareness and training to sustainable financing reaching entrepreneurs previously excluded from traditional development programs.”

Dr Alam highlights the sustainability of RECP practices. “The outstanding economic benefits we have achieved including impressive cost reductions of 20-30% and exceptional product quality improvements create powerful momentum for widespread adoption. The dynamic peer-to-peer learning networks, exemplified by inspiring success stories like Sarkar’s foundry transformation, are generating an unstoppable wave of knowledge sharing and continuous innovation.”

Sarkar’s transformation has made his business a local leader in green industrial practices. He now shares his knowledge with other foundry owners, promoting eco-friendly methods. His vision continues to grow, as he plans to add a heat treatment plant, a metal testing lab, and a solar energy system.

GUK is working to provide financial and technical support to 1,000 microenterprises in Bagura and Naogaon districts under the ‘Promoting Sustainable Growth in Machinery and Equipment Sub-Sector through RECP Practices’ sub-project of the SMART project. With support from the government of Bangladesh and the World Bank, PKSF is implementing the SMART project across the country to support around 80,000 microenterprises in Agriculture, Manufacturing and Processing, and Service sectors within 2028. The main objective of the project is to increase resource-efficient and resilient green growth of microenterprises.